1.) Drive Belt

In both gas and electric dryers, a belt is used to rotate the drum. Over time, this belt can become hard and brittle and portions of the belt may separate. This can cause a thumping noise when the drum is turning. Belts can be visually inspected by removing the front panel or lifting the main top on some models. If the belt shows any signs of cracking or fraying then it should be replaced with the appropriate dryer repair parts.

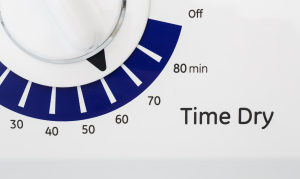

2.) Timer

The timer is located in the control panel of the dryer. It consists of a small motor that’s connected to a series of gears. The gears rotate cams which turn electric contacts off and on inside the timer. These contacts also control the dryer motor as well as the heat circuit and the timer motor itself. These contacts can be checked with a multi-meter, but this test should only be made with the power removed from the dryer. If there is a defect in either the timer motor or the timer’s electrical contacts, then the timer will need to be replaced with the appropriate dryer repair parts.

The timer is located in the control panel of the dryer. It consists of a small motor that’s connected to a series of gears. The gears rotate cams which turn electric contacts off and on inside the timer. These contacts also control the dryer motor as well as the heat circuit and the timer motor itself. These contacts can be checked with a multi-meter, but this test should only be made with the power removed from the dryer. If there is a defect in either the timer motor or the timer’s electrical contacts, then the timer will need to be replaced with the appropriate dryer repair parts.

3.) Cycling Thermostat

The cycling thermostat in your dryer monitors the temperature and turns heat on and off to maintain the right temperature. If the thermostat cannot sense the temperature accurately, the heater may stay on too long and create a safety hazard. The cycling thermostat has contacts that are normally closed, but open when the temperature rises. Therefore, testing for continuity will not necessarily determine if the thermostat is defective. You should first inspect the blower wheel, exhaust vent, drive motor and drum seals to verify that you have proper airflow before replacing the cycling thermostat. A buildup of lint or other foreign material on the back of the thermostat will also insulate it and prevent it from sensing the proper temperature. Power should be turned off before attempting this repair.

4.) Door Switch

The door switch keeps the dryer from tumbling unless the door is firmly closed. If the door is closed firmly and the dryer does not start, then the switch may be defective. The switch can be found protruding into the door opening from behind the front panel. The switch may have 2 or more terminals and can be tested for continuity with a multi-tester. The test should be made between the terminals marked “C” and “NO.” When the door is closed or the button is depressed it should read 0 ohms. Be sure and remove power completely before performing this test.

5.) Start Switch

When the start switch is depressed it sends power to the drive motor, which starts the dryer tumbling. If the dryer doesn’t start then the start switch may be defective. The switch can be tested for continuity using a multi-meter, but be sure and unplug the dryer before testing the switch.

When the start switch is depressed it sends power to the drive motor, which starts the dryer tumbling. If the dryer doesn’t start then the start switch may be defective. The switch can be tested for continuity using a multi-meter, but be sure and unplug the dryer before testing the switch.

Once you have determined the issue with your dryer, many parts are easy to replace. Should you find yourself in a situation where the repair demands more than your skills, however, Dr. Duct is always just a short phone call away. Call Dr. Duct at 613-845-0707.